Much of Muncie’s history is tied to the Ball Brothers, five New York industrialists who moved their fledgling glass business here in the 1880s. Although the company’s Muncie glassworks closed in 1962, a colossal physical reminder of Ball’s industrial omnipotence here is a mysterious tower left behind on East Memorial Drive.

You don’t need to be from Muncie to be familiar with the Ball brothers. You know their name and the product that made them famous if you’ve ever “put up” green beans or pickles or had grandparents who canned. The enterprise that later became Ball Corporation started in 1880, when two of the brothers, Frank and Edmund, bought the Wooden Jacket Can Company in Buffalo.

The business made wood-enveloped tin cans to hold volatile materials like kerosene and varnish, and brothers Lucius, William, and George joined the company soon after Frank and Edmund acquired it1. In 1884, the brothers discovered that John Landis Mason’s fruit jar patent expired. They started making them themselves, and a legacy was born2!

It didn’t take long for Ball jars to become ubiquitous. The company’s mason jars featured a molded glass thread around the rim that allowed a lid to be screwed directly to a part of the jar known as the bead. Others used a wire bail assembly to clamp a glass lid to the rim. Traditionally, both styles of containers were used for preserving food but experienced a hipster resurgence during the 2010s as drinkware, or for storage and DIY projects. Today, they’re cherished by many as timeless and versatile accessories.

Ball jars made in Buffalo are rare and expensive. Very few still exist, since officials lured the brothers to Muncie shortly after the company began making them! Boosters promised the brothers seven acres to build a factory, along with a gas well, a rail spur, and $5,000 cash3. It was too much to ignore, so the Ball Brothers Manufacturing Company opened its first Muncie plant in 1888, and the rest of the company’s operations moved to the city the following year.

Over the next half-century, the company absorbed smaller competitors like the Swayzee Glass Company, the Port Glass Company, the Marion Fruit Jar & Bottle Company, and many others. Ball grew to become a juggernaut in the home-canning industry! Jars branded Eclipse, Improved, Ideal, Perfect Mason, and Perfection, among others, dominated the market.

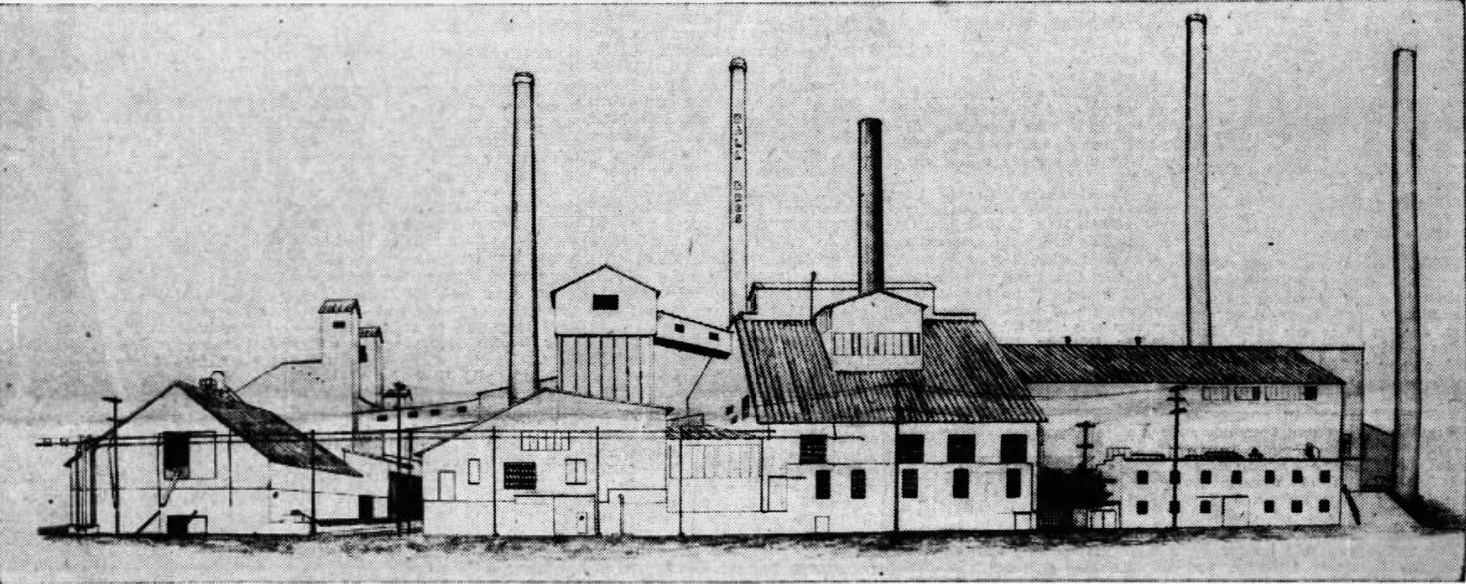

Naturally, the brothers’ factory expanded as well. It eventually spanned seventy-two acres on both sides of Memorial Drive in an enormous block bounded by East 8th Street, Macedonia Avenue, 18th Street, and South Penn and South Blaine Streets. Despite its growth, the company suffered its first operating loss in the years following World War II4. To address the shortcomings of its aging facilities, Ball began a $4.5 million modernization project of its Muncie plant in 1950. That’s $56 million today!

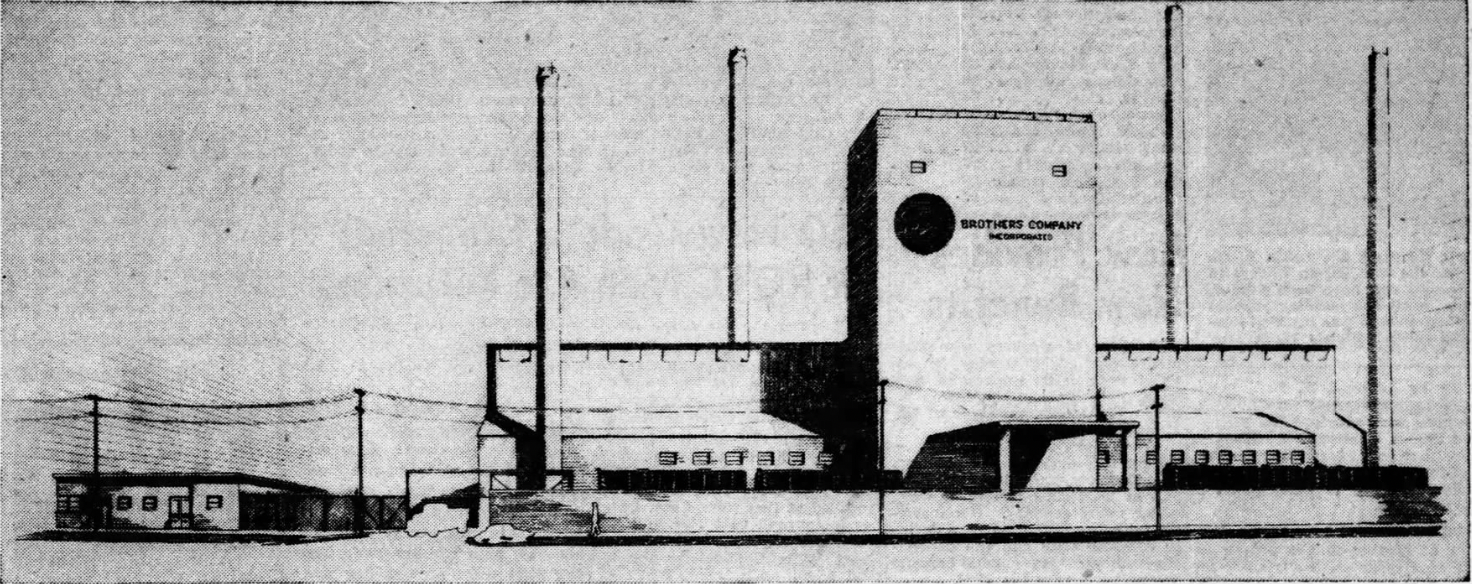

A $680,000 glass tank in the No. 2 factory that cost the equivalent of $7.7 million today was installed in June 1953. The company anticipated four more glass lines to get the same treatment within a year5. When all was said and done, Ball’s second plant featured four of the most modern glass lines in the industry, and they were hungry for raw materials. That’s where the batch tower came in.

I’ve heard several bizarre theories about what the old tower was used for. The craziest, relayed by someone who worked at a factory on the site, was that it was an old helicopter landing pad for the Ball Brothers! The tower’s real purpose was much more sedate: it served to take raw glassmaking materials from railcars, store them, move them to be mixed, and then send the mixes to Plant 2’s furnaces6.

Here’s how the system worked: glass ingredients like sand, soda ash, lime, and cullet were received by railcars that entered on a new, double spur track of Ball’s Muncie & Western Line in front of the tower. The materials were unloaded automatically, elevating them to the top of the structure to be distributed into fourteen unique storage bins. From there, ingredients were transported to a weighing room to be measured into batches. Finally, the tower sent the mixed materials back to the distribution floor to be discharged to four of the factory’s furnaces by conveyor belt. The longest belt transported materials from the batch tower to the plant’s No. 4 furnace, a hundred and fifty feet away7.

John Klug, a famous industrial designer from New York, was responsible for laying out the mixing plant inside the 132-foot-tall tower8, which was engineered from 4,500 cubic yards of reinforced concrete continuously poured in a slipform method9. The structure was dedicated on August 25, 1954, in a ceremony attended by company officials Edmund F. Ball, John Fisher, H.L. Maranda, and local union presidents. At ninety-one, George A. Ball, last of the Ball Brothers, was still active in the company at but did not attend the tower’s dedication. A.J. Davis, a longtime mason for the company who had retired six months earlier, returned to install a commemorative plaque on the tower’s wall10.

The batch tower represented “the most modern and automatic unit of its type anywhere in the world,” said Ball’s director of central engineering services11, commenting that nearly three years went into designing and securing the best apparatus to help the company improve its facilities.

“This structure is a monument to progress, symbolic of our company’s faith in our business, our industry, and our community,” Ball President Edmund F. Ball, the son of founding brother Edmund B. Ball echoed. “But the the best machinery, plants, and equipment in the world are worthless without good people, able and willing to operate them12.”

The monumental tower and new glassworks added to Ball’s massive, labyrinthine campus, some of which still dated to the company’s earliest years in Muncie. Most of the plant’s buildings were connected by a maze of tunnels and catwalks. The batch tower was no different, connected to structures on the north side of Memorial Avenue by a tunnel that went under the street13.

Despite its position at the cutting edge of glass manufacturing, the batch tower was only used for eight years. On July 13, 1962, the company announced that glass production in Muncie would end the following March, citing the age and layout of its facilities, the health of Ball’s eleven other glass plants, high shipping costs from Muncie, and worker inefficiency. “I am terribly sorry this is the conclusion,” said Edmund F. Ball at the time of the announcement14.

“While the decision was an extremely difficult one to make in view of our company’s long association with the community of Muncie,” Ed Ball said at the company’s annual stockholder’s meeting, “the discontinuance of glass manufacturing in that plant…will put an end to the heavy drain of financial resources and management energies those two operations have been exacting for many years. Relieved of the burdens, and left with our several profitable and growing divisions…Ball Brothers’ outlook should indeed be bright15.”

Although eight hundred people remained employed at the company’s headquarters, zinc and metal mills, research facilities, and maintenance forces, the news was devastating. Thirty acres of factory space became obsolete, and six hundred people lost their jobs, as Ball’s last Muncie glass came off the line at 5:03 a.m. on Monday, March 19, 196216.

Ball demolished portions of the No. 1 and No. 3 glass plants north of Memorial Drive shortly after glass production ended, and much of Plant 2 south of the batch tower was torn down in the 1980s. Despite that, the tower stood steadfastly through the destruction. By 1993, the renamed Ball Corporation had continued its diversification into avionics, aerospace systems, and metal beverage cans. That year, it spun seven of its smallest businesses, including its canning products and plastics packaging divisions, off into a new company called Alltrista Corporation17. Ball exited the glass business entirely in 1996, and left Muncie two years later to establish a new headquarters at its existing office in Broomfield, Colorado18.

Despite the loss of the company that bears their name, the spirit of the Ball Brothers is still intact in Muncie, from Ball State University to IU Health Ball Memorial Hospital, Cornerstone Center for the Arts, and several of the family’s philanthropic foundations. The city even still retains some Ball manufacturing heritage: after years of spin-offs, mergers, and acquisitions, Spartech Plastics continues to make coextruded multi-layer barrier roll stock plastic in old Ball facilities, while Newell Brands manufactures lids and bands for Ball branded canning jars from part of Ball’s former No. 1 glass factory across the street.

The batch tower sits between the two factories as a Southside landmark. Along with nearly thirty surrounding acres, Ball still owns the tower and is even said to dispatch a painting crew to touch it up every few years19. More than six decades after it was built, the tower is still one of Muncie’s tallest buildings- my drone can spy on it from my house four and a half miles away despite all the Canadian wildfire haze! Outside of church spires, only the ATT Building downtown, Teachers College at Ball State, and Ball Memorial Hospital rise higher into the sky. Barely.

I’m passionate about the history of Ball Corporation in Muncie since, like so many people here, I have a personal connection to the brand. In 2002, Alltrista -the consumer-centric Ball spinoff- evolved into Jarden Corporation. Nine years later, I was hired to get their backlog of canning question emails under control before I transitioned to marketing and played a pivotal role in several cool projects just as mason jars were surging in popularity.

After Jarden merged with Newell-Rubbermaid and became Newell Brands, I worked in part of Ball Brothers’ old Glass Plant No. 1 as a quality analyst and acting operations supervisor for the closure plant. Despite challenging headwinds, working there was a great experience for a history fan. It provided opportunities to see Ball’s old glass batch tower from unique angles that are unavailable to passerby!

My professional proximity to the old batch tower led me to believe that mysterious landmarks are compelling because they’re tangible connections to the past, so long as people can attribute some history to them. Much of Muncie’s legacy looms over the Thomas Park, Industry, and Blaine neighborhoods in the form of the tower! I’m glad the structure still stands and dominates Muncie’s skyline. It’s a connection to the industries that put our city on the map, and the tower deserves to be celebrated even in its abandoned state.

Sources Cited

1 Quigley, B. (2015). Indiana’s 200: The People Who Shaped the Hoosier State. Indiana Historical Society Press [Indianapolis]. Book.

2 Birmingham, F. (1980). Ball Corporation, The First Century. Curtis Publishing Company [Indianapolis]. Book.

3 Ball Brothers Glass Factory Moved To Muncie In 1886 (1943, March 19). The Muncie Star. p. 11.

4 (See footnote 2).

5 Junk, B. (1953, June 4). New Glass Tank, Laboratory Lead Ball Brothers Modernization. The Muncie Evening Press. p. 1.

6 Francisco, B. (1999, January 4). Towering presence. The Muncie Star Press. p. 7.

7 Junk, B. (1954, August 25). Batch-Mix Plant Work Under Way. The Muncie Evening Press. p. 1.

8 Ceremonies Mark Start of Ball Brothers Building (1954, August 26). The Muncie Star. p. 2.

9 Greene, D. (1954, November 18). Seen and Heard in Our Neighborhood. The Muncie Star. p. 6.

10 (See footnote 5).

11 (See footnote 5).

12 (See footnote 5).

13 Shideler, T. (2023, June 10). My own experience. I’ve been in the tunnels.

14 Ball Brothers to Shut Down Glass Tanks (1962, January 14). The Muncie Star. p. 1.

15 Ball Brothers Stockholders Hear of OSO (1962, March 16). The Muncie Star. Pp. 1-2.

16 Last Glass Is Produced at Ball Factory (1962, March 20). The Muncie Evening Press. p. 2.

17 Brown, D. (1994, September 25). Making a name for themselves. The Muncie Star. p. 37.

18 Penticuff, D. (1998, February 5). Ball Rolls West. The Muncie Star Press. p. 1.

19 (See footnote 6).

This was more than I ever knew about Ball Corp and its history, and was a great read! Sadly, this story has played out hundreds of times in mid-sized communities all across the country.

LikeLike